Centrifugal Slurry Pump

Product Overview

Slurry pump is a centrifugal pump in principle. Conceptually, it refers to a device that converts electrical energy into kinetic energy and potential energy of the medium by means of centrifugal force (rotation of the impeller of the pump), which increases the energy of the solid and liquid mixed medium. It is mainly used in mining, power plant, dredging, metallurgy, chemical industry, building materials and petroleum industry. The name of the slurry pump is a centrifugal pump divided from the point of view of the conveying medium.

In addition, slurry pumps can be divided into different types from different angles. In addition to pumping water, the pump can also pump gas, solid, solid liquid mixture - mineral powder mud! Pump electricity accounts for a large proportion in the country's total electricity, the energy saving of the pump has an important impact on the national economy, the pump not only plays a positive role in the energy saving link, but also plays an important role in the thermal power generation emission

reduction process. At the same time, the slurry pump is 4%-8% more energy efficient than similar products.

Main Features

▶Metals: A05, A07, A33, A49, Cr30, 304 stainless steel, 316 stainless steel, duplex stainless steel

▶Rubber: R55, EPDM rubber, Hypalon

▶Resin: polyurethane, polyether ester

▶Ceramics: silicon carbide

Main Features

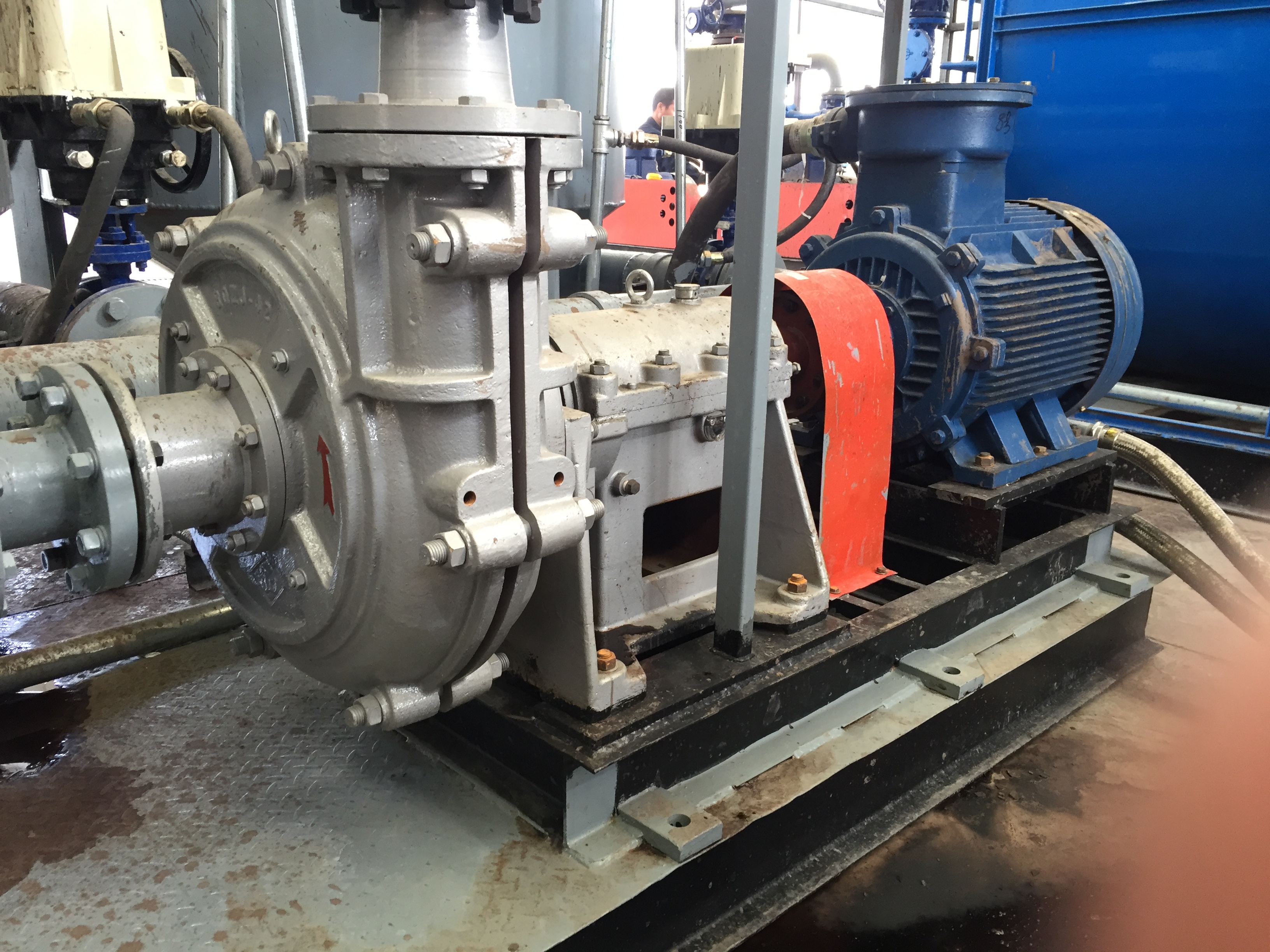

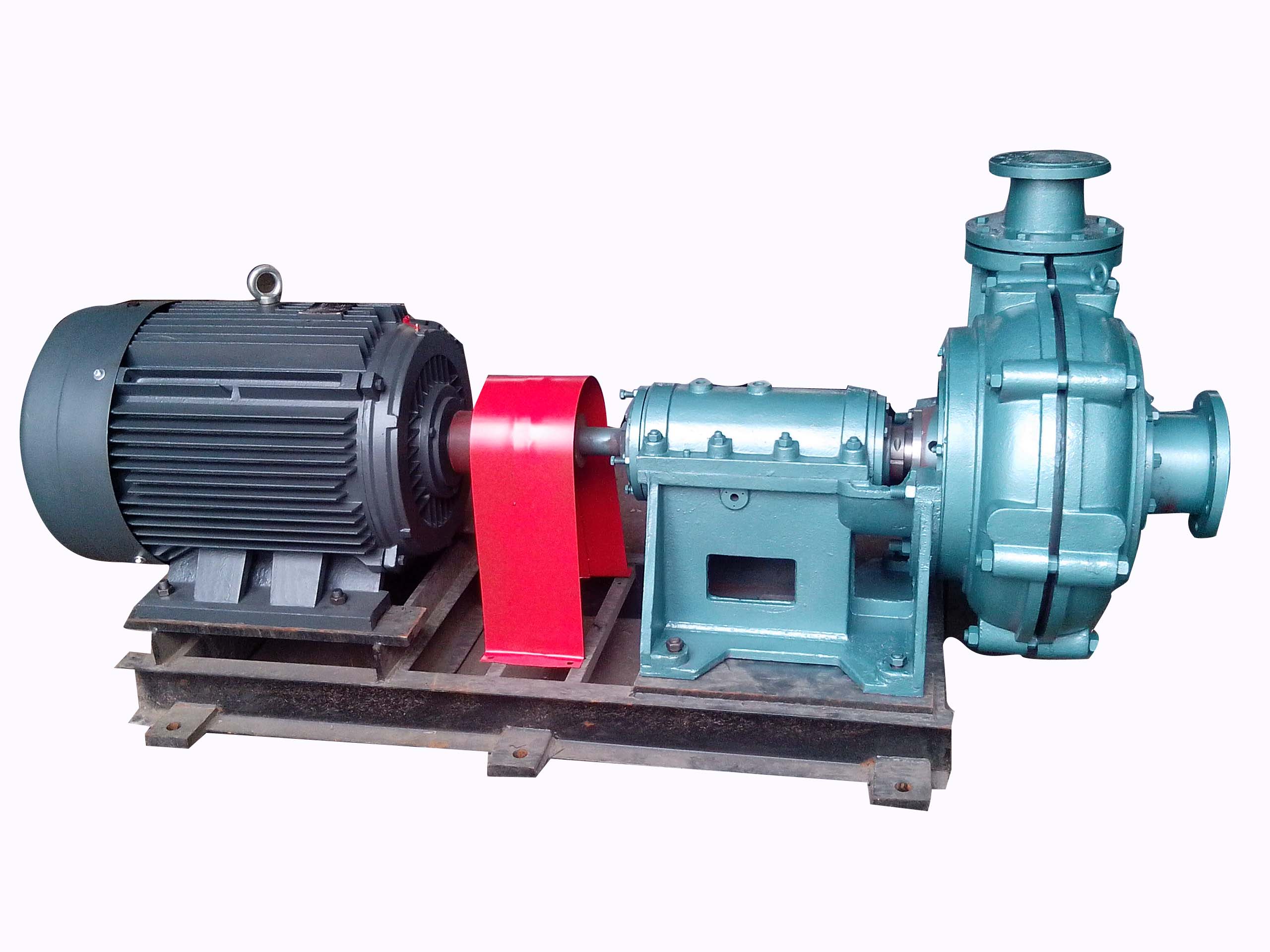

The slurry pump carries a mixture of solid particles containing slag and water. However, in principle, the slurry pump belongs to a kind of centrifugal pump, which is mainly used for the mud transport of converter dust removal water, blast furnace gas washing water, continuous casting turbid-ring water and rolling steel turbid-ring water systems in iron and steel enterprises.

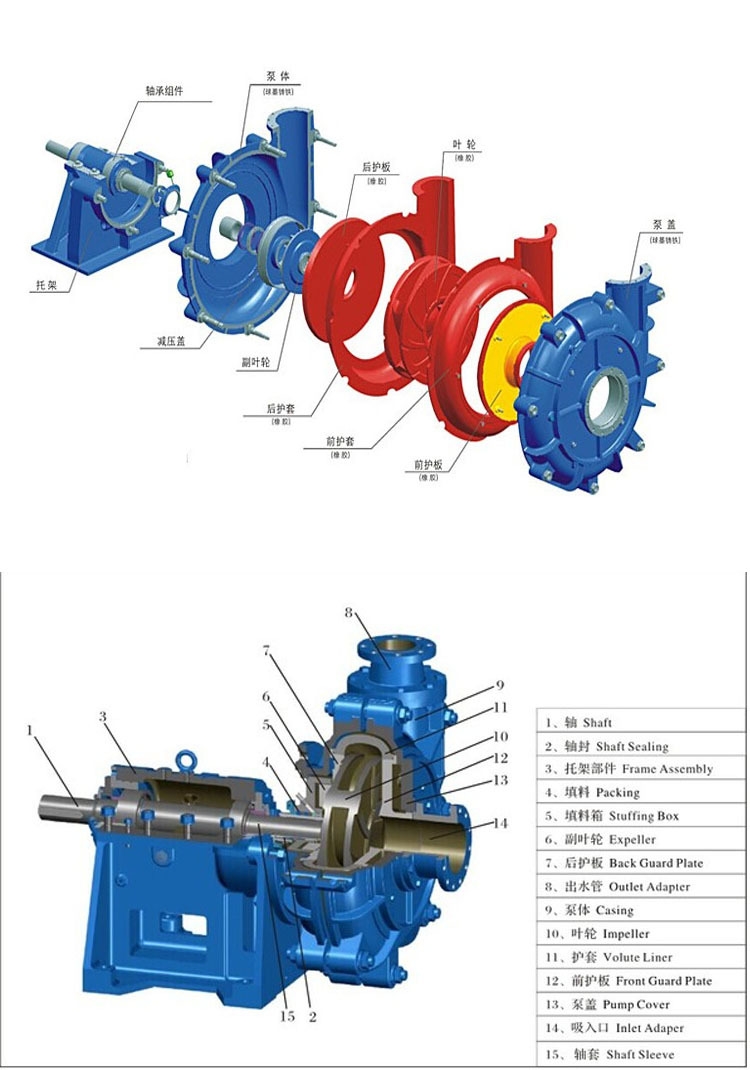

The commonly used slurry pump structure is as follows.

▶(1) Pump head structure. The pump body adopts a double-layer pump shell (internal and external double-layer metal structure), and the double pump shell shell structure is vertically open, and the water outlet position can be rotated by 45° interval and installed in 8 different positions. In order to effectively prevent shaft seal leakage, power seal, packing seal or mechanical seal combination form. The labyrinth gap seal is arranged between the impeller and the rear protection plate, which greatly reduces the leakage of the slurry to the packing box and effectively ensures the reliability of the seal. The impeller is equipped with a back blade to discharge the backflow slurry in time, so as to improve the volume ratio, reduce the backflow and erosion, and improve the life of the flow parts. In order to facilitate maintenance and disassembly, a disassembly ring is provided to avoid the phenomenon of shaft cutting caused by non-disassembly.

▶(2) Bracket structure. The structure of the bracket is horizontally open, and in order to extend the service life of the bearing, the hydraulic design and structural design are optimized. The radial force and axial force are reasonably distributed, and the bearing form, model, cooling and lubrication method are correctly selected, so as to achieve the requirements of low heat and high life of the bearing.

▶(3) shaft seal form. The shaft seal device acts as a seal between the pump body and the pump shaft. Prevents air intrusion into the pump and a large amount of water from leaking out of the pump. The sealing form of the centrifugal slurry pump is usually the auxiliary impeller packing seal, the auxiliary impeller packing seal is a hydrodynamic seal, and the pressure head generated by the auxiliary impeller is resistant to the external leakage of the impeller outlet liquid, and the impeller cover plate is equipped with a water seal ring and filler on the back blade to prevent air entry, and the back blade and water seal ring are used to reduce the pressure at the packing place, which prevents impurities from entering the seal.

Start conditon

The conditions for starting the slurry pump are as follows:

▶(1) Check the slurry pump according to the routine inspection requirements of the pump before starting.

▶(2) Confirm that the slurry pump pipeline has been opened, the thickening bin has been selected, the inlet water door has been opened, the selected thickener has been operated, the thickener slagging door and the washing door have been closed, and the slagging pump has been interlocked.

▶(3) Check that there is no debris in the slag pond, and the water level is greater than 1.2m.

▶(4) Check that the turbator corresponding to the slurry pump has been started and is normal.

▶(5) Adjust the slurry pump frequency converter to less than 10%.

▶(6) Start the slurry pump on the DCS, and slowly adjust the frequency of the inverter after the outlet valve is fully opened, so that it can meet the water volume of the reuse pool.

▶(7) After the slurry pump starts normally, pay attention to the coordination of the slurry pump effluent, the reuse pump effluent and the water temperature of the slag extraction machine.

Debugging and running

The test run of the slurry pump shall meet the following requirements:

▶(1) The steering of the drive motor should be the same as the steering of the pump;

▶(2) The fixed connection parts should not be loose, and the specifications and quantities of lubricants filled in each lubrication part should comply with the provisions of the equipment technical file;

▶(3) the parts with pre-lubrication requirements should be pre-lubricated according to the provisions;

▶(4) Each indicating instrument and safety protection device should be sensitive, accurate and reliable;

▶(5) Turning should be flexible, no abnormal phenomenon;

▶(6) The high temperature pump should be preheated before the test run, and the temperature should rise evenly, and the temperature rise per hour should not be greater than 500%; The temperature difference between the surface of the pump and the process pipeline with the inlet of the working medium should not be greater than 400℃;

▶(7) Set a connection device to eliminate the impact of temperature rise, and set a bypass connection device to provide cooling water.

Matters needing attention

Slurry pump operation should pay attention to the following points:

▶(1) No waterless operation is prohibited, do not adjust the suction population to reduce the displacement, and do not operate at too low a flow rate;

▶(2) Monitor the operation process, completely prevent the leakage of the stuffing box, and use new stuffing when replacing the stuffing box;

▶(3) Ensure that the mechanical seal has sufficient flushing water flow, and the water-cooled bearing is prohibited from using excessive water flow;

▶(4) Do not use too much lubricant;

▶(5) Check according to the recommended cycle; Establish operation records, including operation hours, adjustment and replacement of fillers, addition of lubricants and other maintenance measures and times; The suction and discharge pressure of the centrifugal pump, the flow rate, the input power, the temperature of the lotion and the bearing and the vibration should be measured and recorded regularly.

Application Range

▶Thermal power plant hydraulic ash removal

▶Slurry transport in metallurgical concentrator

▶Coal wash mill coal slurry

▶Shield machine slurry pump