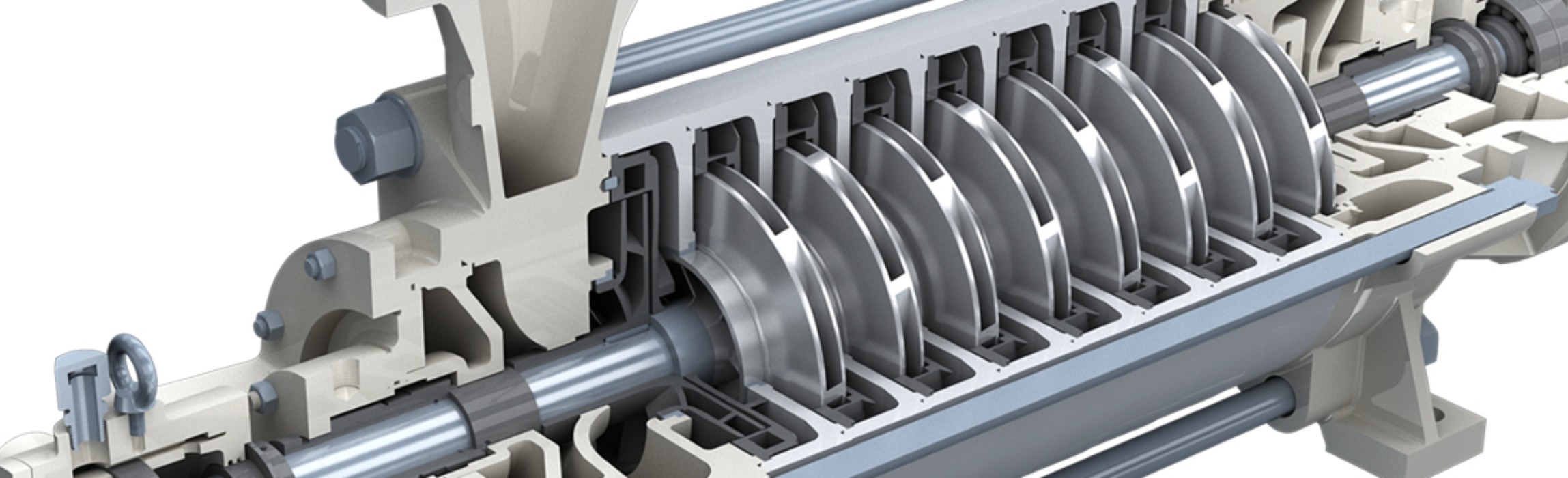

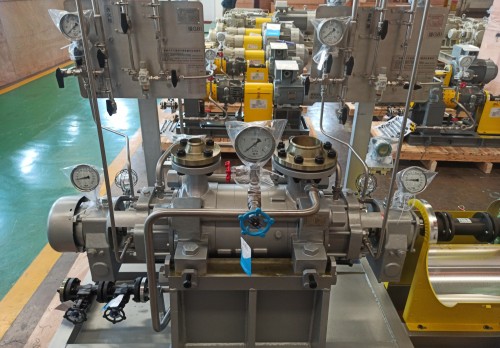

API610 BB4,MBD Series Single-casing, radially split, multistage, between-bearings pumps

Product Overview

MBD series is radial split, two ends supported, guide vane type, first stage single suction or double suction, single filling horizontal multistage centrifugal pump; It is suitable for waste incineration plant, petroleum refining industry, petrochemical process, power industry, conveying oil without solid particles, refined oil, liquefied petroleum gas and other flammable and explosive or toxic high temperature and high pressure liquids.

According to the API610 "centrifugal pumps for the oil, petrochemical and natural gas industry" standard, the series of pumps are modular design, fully considering the user's investment cost and use cost, optimized to ensure the best pump efficiency.

Main Features

▶Follow API 610 standard

▶Reliable,high efficiency ,low NPSH

▶Heavy-duty bearing structure design, can be equipped with various sliding bearings

Smooth operation and high reliability

▶Applicable to ASME/DIN/ISO standards

▶Radial split, two-end support, multi-level segmental structure, center support and foot support;

▶The suction section, the spit section and the middle section are made of integral casting processing,

without manufacturing defects, and the service life can be guaranteed for at least 20 years

▶The pump shaft adopts rigid design, small static deflection, the maximum stage of the pump can

reach 15 stages, the operation is balanced, and the vibration is low;

▶The axial force is fully balanced by the balance disc or balance drum combined structure, and the

thrust bearing bears the residual axial force and protects the mechanical seal;

▶Rolling bearings and plain bearings can be used; Bearing body can be cooled by water, when the

medium temperature is not higher than 120℃, no cooling is required;

▶Various packaged mechanical seals can be installed in accordance with API682 standards to meet the r equirements of different working conditions;

▶The bearing can be lubricated with independent oil station under heavy load;

▶It can be equipped with temperature, pressure, vibration, displacement and other monitoring instrume nts to DCS to provide real-time monitoring and protection of unit operation status.

Performance Range

▶Capacity: Up to 700 m3/h

▶Head : Up to 1400 m

▶Pressure: Up to 15.0MPa

▶Teperature: From -45 to 200 ℃

▶Nozzle size: DN25 to DN200 mm

▶Speed : 2980/3550 rpm

Materials Range

Main materials: In line with API610 standards

▶S-5

▶S-6

▶S-8

▶C-6

▶A-7

▶A-8

▶D-1

▶D-2

▶other material grades, but also according to user requirements for special design

Application Range

▶Oilfield water injection

▶Boiler feed water

▶Petrochemical

▶Pipeline pressurization

▶Refrigeration engineering