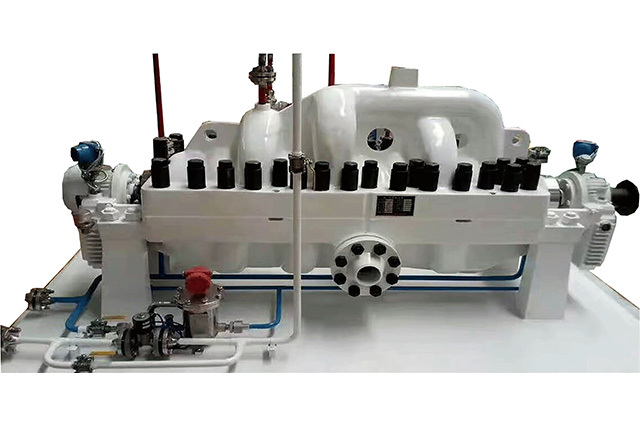

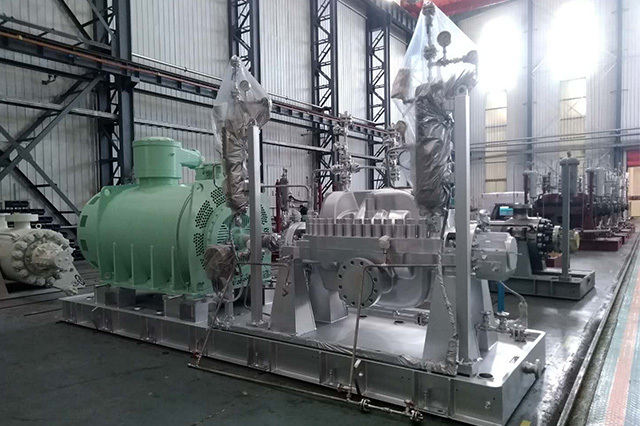

API610 BB3,MBC Series Axially split, multistage, between-bearings pumps

Product Overview

MBC series multi-stage centrifugal pump adopts axial split two end support structure, implements the API610 "centrifugal pump for petroleum, petrochemical and natural gas industry" standard, for heavy-duty type, horizontal axial split, both ends of the support, quasi-center line installation centrifugal pump, suitable for heavy-duty occasions.

This series of pumps is simple in structure, easy to maintain and has high reliability. The entire rotor can be replaced within 8 hours, and maintenance and replacement parts do not need to move the inlet and outlet pipes and motors. This series has become a new generation of heavy duty process pump with its unique high efficiency and energy saving, reliability, high temperature and high pressure resistance, and can be widely used in various industrial cities.

Main Features

▶Follow API 610 standard

▶Near center line support, heavy load design

▶The impeller and the pump body are provided with a wear-resistant ring that can be easily removed

▶Low cavitation, high efficiency

▶Applicable to ASME/DIN/ISO standards

▶All components are interchangeable to the maximum extent possible

▶Flexible design, wide range of applicable media

▶Axial and radial forces are balanced by symmetrical distribution of impeller and volute shell

▶Interference fit is adopted between impeller and shaft

▶The coupling has an extended section, and the motor and pipeline need not be removed when the

pump is removed, and the maintenance is convenient

Performance Range

▶Capacity: Up to 3000 m3/h

▶Head : Up to 2500 m

▶Pressure: Up to 25.0MPa

▶Teperature: From -45 to 200 ℃

▶Nozzle size: DN80 to DN400 mm

▶Speed : 2980/3550 rpm

Materials Range

Main materials: In line with API610 standards

▶S-5

▶S-6

▶S-8

▶C-6

▶A-7

▶A-8

▶D-1

▶D-2

▶other material grades, but also according to user requirements for special design

Application Range

▶Long-distance crude oil pipeline

▶Oil refinery, petrochemical plant

▶High pressure water injection

▶Boiler feed water

▶Reverse osmosis transport